|

I remember as a

grade-school boy, I would go into our recreation room and play around

an old oak table. The table was round, with four hand-carved legs that

each had the face of a tiger. I would run "pretend" racers around and

around the table, or set up armies and have mock battles. I remember as a

grade-school boy, I would go into our recreation room and play around

an old oak table. The table was round, with four hand-carved legs that

each had the face of a tiger. I would run "pretend" racers around and

around the table, or set up armies and have mock battles.

The table was also the place where we did our ceramics. My dad

was always interested in "artsy" things, so I was introduced early to

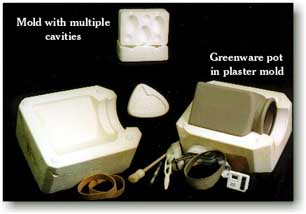

the magic of ceramics. We had plaster molds into which we poured a

brown mud-like substance called "slip." The molds were in two pieces

and were held together by rubber bands. There was a small hole in the

top of each mold. That's where we poured the liquid clay. After about

fifteen minutes, we poured out the clay and then set the molds aside

to dry for about an hour. Then, by removing the rubber bands, we could

carefully open the molds and remove the delicate product.

We had molds of cats, dogs, angels, Nativity figurines, bears,

Santas and many more. The trick was to remove the soft clay pieces

without breaking them. It was also necessary many times to then

assemble arms and legs to the bodies, each step requiring tedious

work. After assembly, they had to dry completely. Once dried, the

various ceramic objects are called "greenware"--they are very easy to

break if accidentally knocked over or bumped together. The greenware

is then painted with a variety of ceramic paints called glaze, each

applied to create a desired finish. I always liked the ones that gave

a "crackled" finish. The different glazes are really simply mixtures

of different rock and mineral compounds that give different colors

once heated to melting. The trick is to know what they will look like

as they are applied, since it often makes a difference which one goes

on first.

Once glazed, the ceramic objects are fired in a kiln. We

had two electric kilns, one large one and one small one. The small one

was about three feet square, with room inside for about two shelves of

ceramics. Each ceramic piece was loaded carefully, because wherever it

was painted it could not sit directly on the shelf. If it did, it

would stick to the shelf during the firing process and be hard to

remove without damaging it. Sometimes we laid the ceramic piece on a

special support that had three pinpoints where the ceramic piece

touched it. In that way a part could be painted all over and it would

only rest on three small supports. Once glazed, the ceramic objects are fired in a kiln. We

had two electric kilns, one large one and one small one. The small one

was about three feet square, with room inside for about two shelves of

ceramics. Each ceramic piece was loaded carefully, because wherever it

was painted it could not sit directly on the shelf. If it did, it

would stick to the shelf during the firing process and be hard to

remove without damaging it. Sometimes we laid the ceramic piece on a

special support that had three pinpoints where the ceramic piece

touched it. In that way a part could be painted all over and it would

only rest on three small supports.

The firing process took all night. We used little devices called

"cones" to control the firing process. These little cones were set

under a little moveable pin inside the kiln. The pin was connected to

an electrical switch that was held in the "on" position as long as the

cone remained rigid. However, as the desired kiln temperature is

reached, the cone begins to soften and finally bends resulting in the

switch being shut off to the kiln. It took almost a full day for the

kiln to cool down after a firing, most of the time being taken to be

sure that it cooled very slowly. If the top were opened while it was

too hot, the ceramics would crack and break by the sudden

chilling.

I once took a mold, some slip, some greenware, some glazed

ceramics and some finished pieces to Speech Class at Tyee Jr. High. I

described the process to the class and gave brief demonstrations how

it was done. It was really interesting to the class and I enjoyed

telling about it. I think I got an "A" on that one. Besides,

afterwards I did a fairly brisk business selling ceramic cats to my

classmates!

Mom really got involved in some wonderful ceramic projects. She

bought the molds for making Nativity figurines. It included the baby

Jesus, a manger, a cow, a donkey, sheep, shepherds, Joseph, Mary, the

three wise men and of course, their camels. She assembled all of them

very carefully and then put glaze on to make them look realistic.

After firing them, she then decorated the Wise Men with cloth and

other decorations so that they were quite realistic. She sold many

sets of them. I even talked her out of a set myself!

Dad was always interested in making new things. He and Clarence

Phipps designed the first electronic potters wheel. At the time, there

were very few electronic devices of this type. It had a control knob

on the side that would allow the wheel to spin at a variable rate. The

wheel could also be controlled by a foot pedal. They even went so far

as to consider selling the units commercially. I don't know what

prevented them.

I remember dad would spend hours forming pots on the wheel.

Sometimes he bought the clay from a ceramics outlet store, but at

other times he would try to find native clay. He would scour the

countryside and find places where he could dig out clay. He'd then try

making pots from the clay and making his own glazes. Sometimes the

colors were really different when he used his own clay and glazes of

his own making.

It was fun trying to make pots and feel the slick clay slip

through my fingers. The only problem was that it was messy and took a

long time to clean up after a session.

Dad also spent time modeling with clay. I still have an

"Indian head" that he was going to throw away. He always was trying to

talk me into letting him make a mold of my face! The way he explained

it, I'd just have to sit in a chair and he would apply plaster to my

face, leaving holes for me to breathe through my nose. Or was it that

he was thinking of poking straws in my nose to breathe through? For

some reason, I was deathly afraid that I wouldn't be able to properly

breathe, or that maybe the plaster wouldn't come off my face after it

had hardened. Besides, I remember that the plaster releases heat as it

hardens, so maybe I was just afraid that I'd fry my face or something.

Instead, he modeled my face in clay. Ron gave me dad's sculpture on

Christmas day 1999. Dad also spent time modeling with clay. I still have an

"Indian head" that he was going to throw away. He always was trying to

talk me into letting him make a mold of my face! The way he explained

it, I'd just have to sit in a chair and he would apply plaster to my

face, leaving holes for me to breathe through my nose. Or was it that

he was thinking of poking straws in my nose to breathe through? For

some reason, I was deathly afraid that I wouldn't be able to properly

breathe, or that maybe the plaster wouldn't come off my face after it

had hardened. Besides, I remember that the plaster releases heat as it

hardens, so maybe I was just afraid that I'd fry my face or something.

Instead, he modeled my face in clay. Ron gave me dad's sculpture on

Christmas day 1999.

|